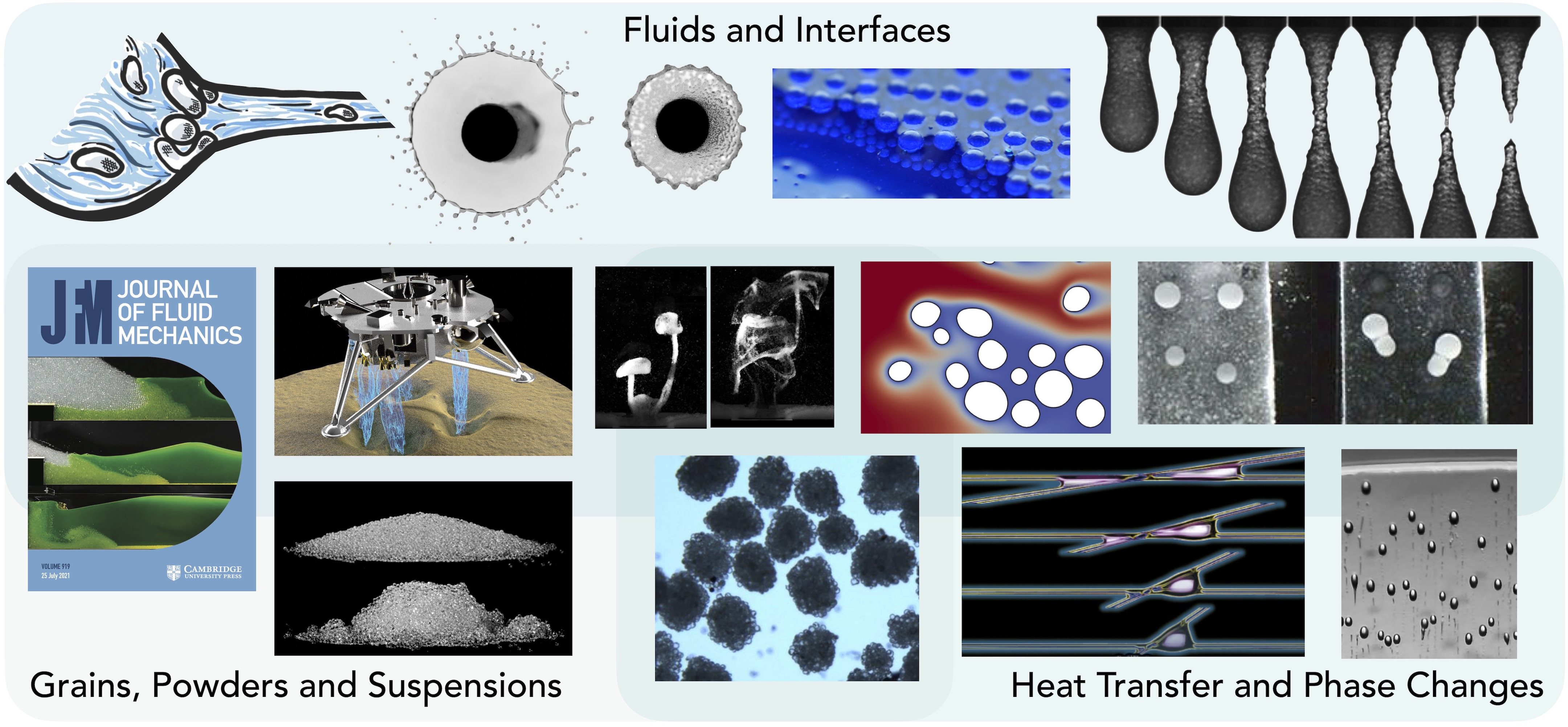

The overarching goal of our lab is to develop general frameworks to describe the dynamics of multiphase systems in various environments, for instance, when confined by interfaces or solid surfaces, when particles cross a fluid-fluid interface, or when some phase change occurs due to heat transfer or chemical processes. We also aim to account for the possible complex nature of the particles (cohesive, flexible, porous, ...). . Our research activities generally entail multiphase systems, such as suspensions of particles, granular materials, immiscible fluid mixtures, droplets, polymers, and solid/liquid/gas phases of the same component. These systems are particularly exciting as they share common features and are involved in numerous situations, from industrial processes to environmental situations. Despite that these systems are common in day-to-day life, they remain poorly understood. Below is a (non-exhaustive) list of current projects our group is working on.

Fluid Mechanics and Soft Matter for Additive Manufacturing

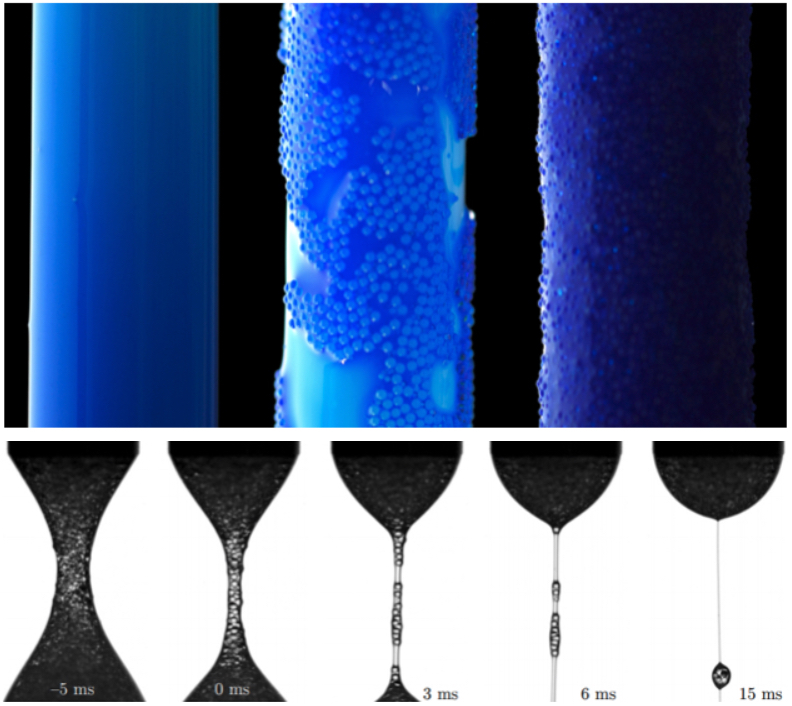

Extrusion-based additive manufacturing is a rapidly growing field with significant applications, but it faces numerous challenges rooted in fluid mechanics, soft matter, and rheology. Our group focuses on addressing critical limitations that arise at various stages of the process. For instance, complex phenomena occur in the reservoir and in the nozzle, during the extrusion (printability and clogging), during the filament and droplet formation, and the final deposition and solidification. Each step is crucial to the success of the process. However, our understanding remains mainly empirical, relying heavily on trial-and-error methods.

We tackle these challenges by trying to describe complex rheological behaviors essential for printability and mechano-rheological performance. Our work investigates clogging mechanisms and the formation and stability of filaments and droplets of complex fluids. In particular, when the liquid used contains dispersed solids, droplets, or bubbles, classical models often fail to capture the interfacial dynamics. Through experimental approaches across scales, we aim to disentangle the bulk behavior of those heterogeneous fluids from local heterogeneities to better understand capillary flows in suspension threads, thin films, and drops. In addition to additive manufacturing, this research enhances industrial processes like spray and dip coating and develops new approaches by leveraging capillary effects to develop more efficient filtration techniques.

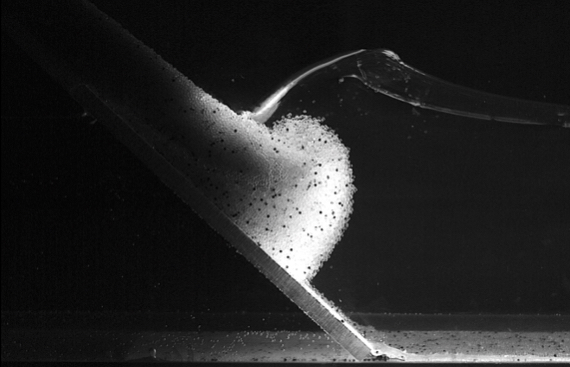

Transport and clogging of particles in complex environments

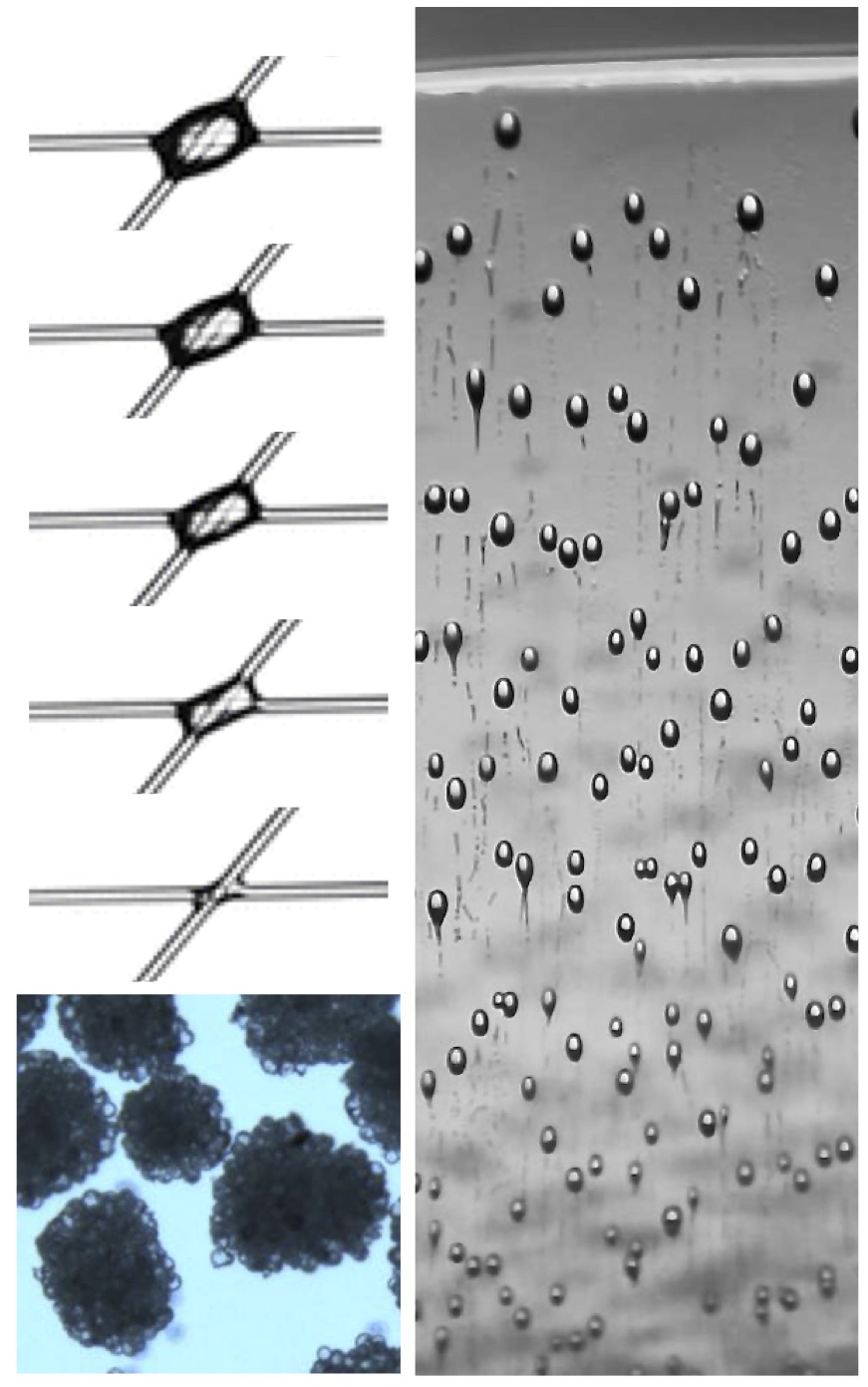

The aggregation of particles and resulting clog formation in confined systems, such as pipes or arteries, have dramatic consequences. When a clog is formed, the particles are no longer transported, and the fluid is transported at a low flow rate. Clogging of a channel can occur through direct obstruction by large particles or fibers (sieving), by forming a bridge (jamming), or by the continuous deposition of microparticles on a channel (aggregation). In filters, this leads to a reduction of the volume filtered. In blood vessels, clogs prevent oxygen from reaching a section of the vascular system. Even at larger scales, clogging occurs. This was demonstrated recently by the blockage of the Suez channel by a container ship that cost an estimated $9.6 billion of trade along the waterway each day. Predicting the dynamics associated with clogging requires modeling the coupling between particles, fluid, and boundaries. However, our understanding of clog formation and prevention is, at best, qualitative and limits the development of resilient systems. Our goal is to characterize, describe and predict the occurrence of clogging in such systems, and engineer innovative methods to prevent or delay clogging.

Phase change, Heat transfer, Reactive Flow

Heat transfer and phase change, such as observed during drying, are important phenomena that play a critical role in a variety of industrial processes. For instance, when drying powders, or fiber networks, the removal of moisture can lead to agglomeration between particles. The rate of heat transfer and the amount of energy required for the phase change depend on the properties of the system, such as its composition, the temperature, the relative humidity, etc. Similarly, in the process of ice formation, the transfer of heat from the surrounding environment to the water causes it to freeze, in which case air bubbles can be trapped in the resulting ice. Modeling these phenomena is crucial in industries such as food processing, pharmaceuticals, and materials science, where the control of heat transfer, phase change, and mechanical input, can significantly impact product quality and efficiency. Our group is currently investigating the drying of powders under shear and the coupling between fluid flow and ice formation.

Influence of cohesion on granular and particle transport

We aim to describe the dynamics of cohesive particulate matter such as grains subject to biological cohesion, dust, powders, snow, or clay. Whereas the last few decades have seen substantial progress in our ability to predict the dynamics of non-cohesive particles, comparable progress has not yet been achieved for cohesive grains. An accurate description of cohesive particles is crucial as the erosion and transport of cohesive materials play a dominant role in numerous industrial applications (handling of powders) and also for a wide range of environmental processes (aeolian soil erosion, erosion by aircraft engines, transport of sediment in oceans and rivers). At present, our understanding of these processes is qualitative at best, and in particular, the influence of biocohesion in submarine particulate flows remains elusive. Accurate modeling requires a quantitative knowledge base, and in particular, the formulation of reliable scaling laws.

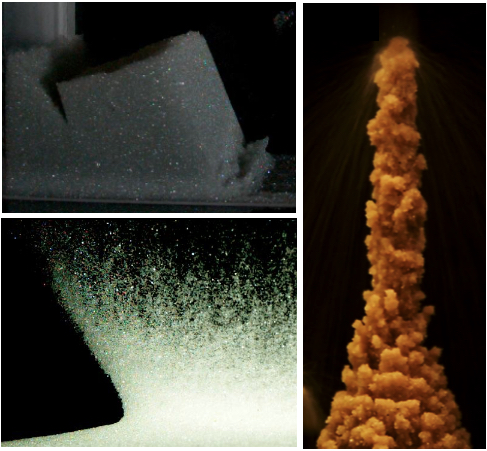

From dry to wet granular material

Granular materials are ubiquitous in many industrial and geophysical processes. Our goal is to describe how dry grains enter into water and lead to a suspension of particles. Although over the past two decades different studies on dry and wet granular media have brought new approaches in their modeling, the transition between these two regimes remains unclear and empirical. This situation encompasses industrial applications (blending of grains and liquid), as well as geophysical processes (tsunami waves generated by landslides, initiation of mudflow), and environmental engineering (irrigation). Understanding how dry grains can get disperse into water to obtain a suspension of particles is a challenging task because of the three phases involve (grains, liquid, air).

Advancing Water-Efficient Agriculture

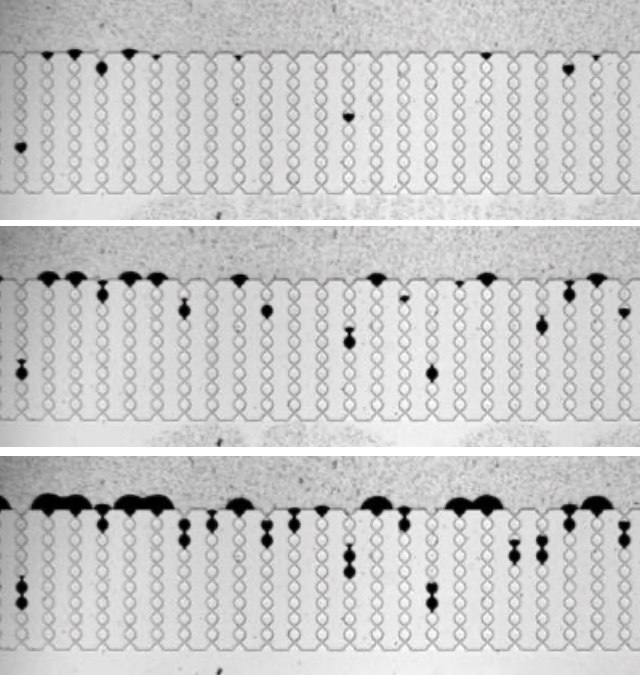

Earth’s growing population, combined with diminishing water resources, is expected to result in nearly six billion people suffering from clean water scarcity by 2050. Agricultural irrigation accounts for 70% of global water use. Therefore, improving agriculture efficiency, particularly irrigation methods, is a critical priority for maximizing clean water availability and increasing overall agricultural production. In particular, we consider drip irrigation, which is a water-saving technology that enhances agricultural efficiency, promotes sustainable practices, and helps underdeveloped communities address water scarcity. However, its adoption is often hindered by physical and biological clogging, which significantly reduces irrigation efficiency.

Our group uses millifluidic experiments to design clog-resistant drip emitters, employing hydrodynamic strategies to minimize material deposition. By leveraging particle image velocimetry (PIV), we study the fundamental hydrodynamic behavior within emitters and directly visualize the performance evolution of new designs over time. This approach aims to advance drip irrigation technology and improve its reliability in diverse settings.